Sustainability

OUR COMMITMENT

At Bantam Materials UK Ltd., we believe that people are at the heart of every business, and when they are treated with respect, work in decent conditions and earn fair rates of pay, both they and their companies benefit from increased commitment, productivity and better-quality material.

Bantam Materials is committed to respecting human rights and supports the UN Universal Declaration of Human Rights, the International Labour Fundamental Principles and Rights at Work, the UN Guiding Principles on Business and Human Rights and the Ethical Trading Initiative (ETI) Base Code. We recognise that while states have a responsibility to protect human rights, we as a business have a responsibility to respect them.

Bantam Materials requires its value chain partners to comply with all applicable laws in the countries in which they operate. In addition to legal compliance, suppliers who sell plastic material through the Prevented Ocean Plastic programme are required to meet the Prevented Ocean Plastic Standards and undergo an audit by an external third party.

In honouring our commitment to respect human rights, Bantam Materials set up the Prevented Ocean Plastic Programme, the aim of which is to:

Transform the recycled plastics industry through the development, adoption and promotion of responsible sourcing practices that aim to improve environmental and working conditions in source countries, in alignment with protecting human rights.

OUR KEY PRIORITY AREAS

Traceability

By knowing where our plastic is sourced from, we can take responsibility for the conditions under which the material is collected, sorted and processed. Prevented Ocean Plastic material can be traced back to where the material was collected through Chain of Custody Documentation.

Workers

Workers are the backbone of our value chain and worker rights must be respected by all our suppliers who are part of our programme. We expect our suppliers to abide by our Code of Conduct and respect the Ethical Trading Initiative Base Code.

Environment

Plastic pollution is not only an environmental, but also a social equity issue. We expect all our suppliers to adopt environmentally friendly practices, whilst also respecting human rights.

A Clean Environment for All

In 2022, the United Nations General Assembly, under resolution 76/300 declared that all humans have a right to a clean, healthy, and sustainable environment. This resolution recognizes that the pollution of land and water, as well as the unsound management of waste has negative impacts on the environment and therefor negatively impacts on our right to a clean and healthy environment.By preventing ocean plastic pollution through our recycled plastics business and adopting responsible sourcing practices across the recycled plastics supply chain we work in alignment with resolution 76/300.

Freedom of Association and Collective Bargaining

Bantam Materials respects the rights of all workers to join a union or to bargain collectively in accordance with international law. This right forms an integral part of the ETI Base Code and is included in our Code of Conduct as well as the Prevented Ocean Plastic Standards. As part of our commitment to strengthen freedom of association and collective bargaining in our supply chain, we will be encouraging all Tier 1 suppliers to implement some form of worker representation at their facilities. Our priority will be suppliers whose certification is up for renewal in 2026.

OUR UN SUSTAINABLE DEVELOPMENT GOALS

Goal 14 is about conserving and sustainably using the oceans, seas and marine resources. Healthy oceans and seas are essential to human existence and life on Earth. According to the UN, plastic is the most harmful pollution and 17 million metrics tonnes ends up in the ocean every year. So far we have prevented over two billion plastic bottles from going into the ocean.

Goal 12 is about ensuring sustainable consumption and production patterns, which is key to sustain the livelihoods of current and future generations. We know that consumers find it hard to make environmentally friendly choices– but we’re trying to make it easier. We work with a range of brands to offer a better plastic choice.

Goal 9 seeks to build resilient infrastructure, promote sustainable industrialization and foster innovation. Prevented Ocean Plastic™ builds supports and builds new recycling infrastructure everywhere it operates. Right now, we are on a mission to build 25 new high capacity collection centres by 2025.

Goal 8 is about promoting inclusive and sustainable economic growth, employment and decent work for all. Prevented Ocean Plastic™ promotes the elevation of standards throughout our supply chain. The Prevented Ocean Plastic™ standards promotes worker welfare through the integration of the ETI base code. Bantam Materials UK Ltd., the supplier of Prevented Ocean Plastic™, was the first recycled plastic supplier to join the Ethical Trading Initiative.

OUR INTERNAL GOVERNANCE

A clear governance structure ensures accountability for our responsible sourcing strategy and that practices are implemented across our value chain. Within our company, we work across departments and with regional partners and third-party sustainability experts to address salient risks.

At Bantam Materials, the director oversees the implementation of our responsible sourcing strategy. This strategy is co-developed and coordinated by the Head of Programme Development, in collaboration with the Head of Supplier Development and our Social Impact Consultant. Together, they form our Ethical Trade Team. They are all based at our head office in London.

The Ethical Trade Team meets at least once every quarter to discuss responsible sourcing. Depending on the topic, the team may involve representatives from other departments.

The wider company is informed at our biannual strategy day. Key issues discussed include, but are not limited to the following:

- Strategic objectives and budget

- Supplier development and audit planning

- Ongoing HRDD related projects

The Ethical Trade Team has travelled extensively visiting our suppliers on site and have the authority to act when needed.

We work closely with our regional partners Southeast Asia and East Africa to support with the implementation ofresponsible sourcing practices. They are required to report back to the Ethical Trade Team, whom they are in contact with on a regular, if not daily basis

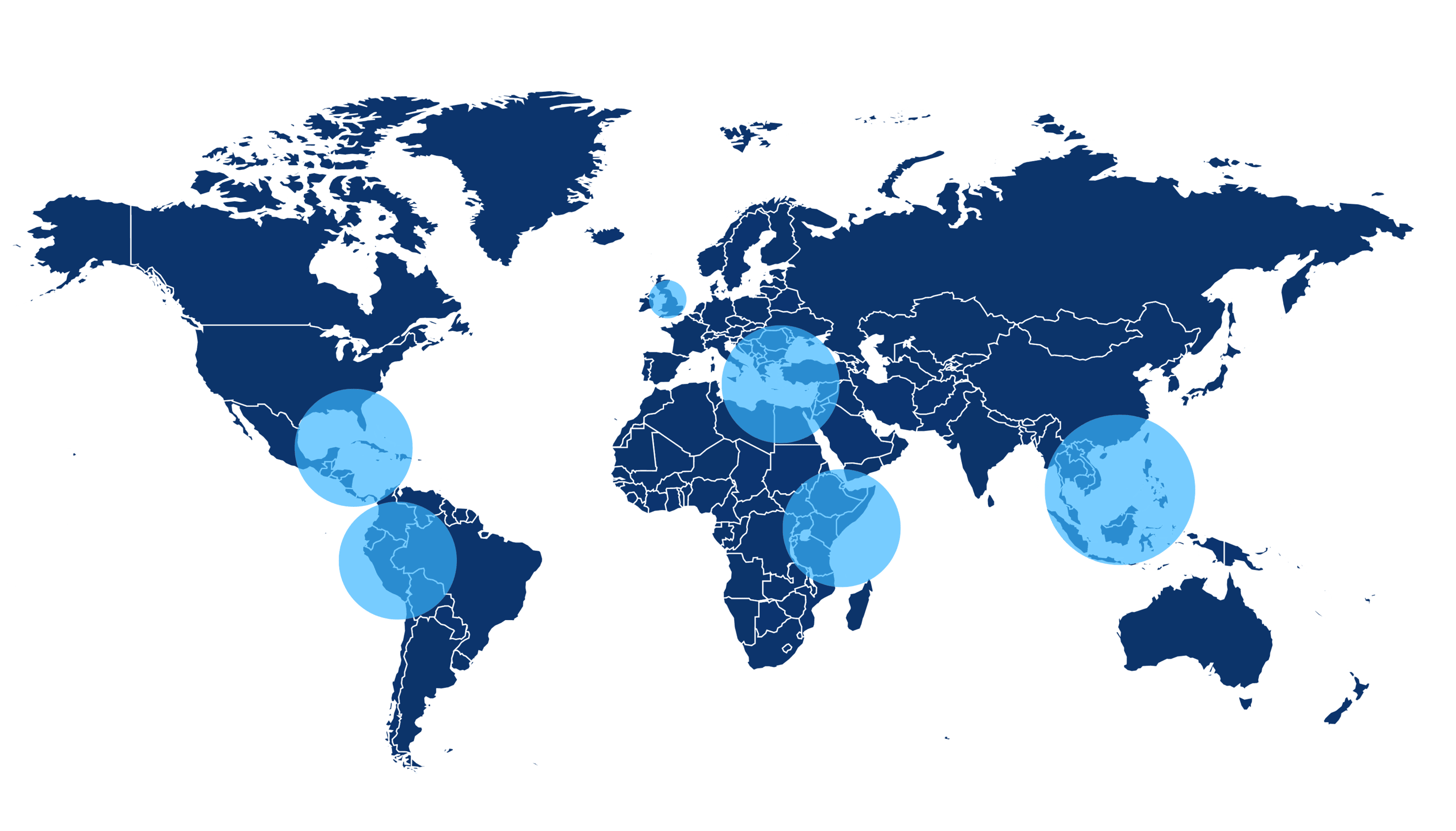

THE RECYCLING MODEL THAT WORKSBUILDSELEVATES AROUND THE WORLD

ABOUT OUR VALUE CHAIN

The Prevented Ocean Plastic Programme works with several Tier 1 suppliers around the world to source and process raw plastic material which can be used for high quality food grade packaging. These facilities purchase postconsumer plastic material, such as PET bottles and PP cups and wash and grind them into flakes. The programme also includes over fifteen Tier 2 Collection and Aggregation Centre facilities. These facilities collect, sort and bale the plastic material before they are sold to the recycling facilities. Many of these facilities are part owned by Prevented Ocean Plastic.

Tier 1 Recycling Facilities.

- Total workers: 1,639

- Male: 65%

- Female 35%

UNDERSTANDING & MITIGATING HUMAN RIGHTS RISKS IN OUR VALUE CHAIN

To understand and mitigate human rights risks in the recycled plastics value chain the Prevented Ocean Plastic Programme adopts several different methods, including desktop country analysis, third party audits, worker surveys and in-depth research studies. Where possible, we collaborate with local, third- party experts to help develop clear recommendations and practical strategies to mitigate salient risks.

Identifying salient human rights issues

We believe in adopting a sector, country and facility-specific approach to identifying and addressing human rights risks.

Our initial desktop analysis was guided by a model developed by SHIFT (2022), designed exclusively for the plastics packaging value chain: Principles for Corporate Engagement on Human Rights with the Informal Waste Sector, based on the UN Guiding Principles on Business and Human Rights.

Using this framework, several additional academic studies and open access resources, such as the ITUC Global Rights Index and the Global Slavery Index were analysed to better understand the root causes and prevalence of each human rights issue per sourcing country. Where possible, the most recent sector-specific data was prioritized over country-specific data to ensure specificity.

Our prioritisation of issues and geographies was in part informed by the UN Guiding Principles Framework, and we considered several factors, including likelihood, severity, scale, scope and our sphere of influence. As a result, we identified that workers, in informally organised tiers of our value chain were most at risk of several interrelated human rights issues. We then narrowed our focus taking into consideration our level influence and geographies with the high production volumes.

We identified informal waste workers, more specifically independent bottle collectors (i.e. waste pickers) within our Indonesian value chain as one of our highest risk priority groups. In 2025, as part of our Lives & Livelihoods Series, we carried out primary research amongst informal waste workers across three islands in Indonesia. The purpose of the study was to obtain a deeper understanding of interrelated human rights risks, working conditions and waste worker needs. The results of the research will be used to further inform our approach and strategy to address the identified human rights risks.

How we monitor & mitigate human rights risks

We apply several methods to assess, mitigate and monitor human rights risks in our value chain. The following practices are applicable to suppliers who are participating in the Prevented Ocean Plastic programme.

Registration: Suppliers are required to officially register their facility by completing a registration form and provide key legal documents, alongside evidence of any existing relevant certifications (e.g. SMETA).

ETI Base Code Self Declaration: Suppliers are requested to complete an ETI Base Code Self Declaration – the purpose of which is to assess their status on meeting the ETI Base Code. The ETI Base Code. The ETI Base Code is a set of labor standards from the Ethical Trading Initiative that sets out minimum conditions for workers in supply chains, based on International Labour Organisation (ILO) conventions.

Code of Conduct: Every year, suppliers are required to sign and return our Code of Conduct which is updated annually.

Value Chain Mapping: We request suppliers to submit up to date value chain data. This allows us to map their value chain and ensure they can meet our social and traceability requirements.

On-site visits: Suppliers are regularly visited on-site by our Ethical Trade Team to better understand and assess their commercial and non-commercial needs.

Audits:To verify whether suppliers meet the requirements of the Prevented Ocean Plastic Standards, they are required to undergo an audit carried out by an external third party. These audits are funded by Bantam Materials. Audits are carried out amongst our Tier 1 suppliers.

Worker Surveys: We also conduct online surveys with workers. This method provides more subjective, ‘worker voice’ data that goes beyond conventional auditing methods. These surveys are primarily carried out amongst Tier 2 suppliers, for whom a full audit may not yet be suitable. In 2025 we completed our first worker survey with 170 workers in our Indonesian supply chain. Based on those results, we implemented several measures to improve working conditions the facilities.

In-depth research and assessment in high-risk tiers: We carry out in-depth research within our highest risk tier which consists of informal waste sector workers. These studies are used to obtain a deeper understanding of interrelated human rights risks, with the purpose of informing mitigation strategy, as well as identifying opportunities to elevate waste worker livelihoods.

OUR ETI MEMBERSHIP

In 2021, Bantam Materials UK Ltd. became the first recycled plastic supplier to join

the Ethical Trading Initiative.

We are the first recycled plastic business to be accepted to the leading alliance of companies, trade unions and NGOs that promotes respect for workers rights around the globe.

In 2024, Bantam Materials became a full member of the Ethical Trading Initiative. Bantam Materials was the first ever recycled plastic business to be accepted to the ETI- a leading alliance of companies, trade unions and NGOs that promotes respect for workers’ rights around the globe and ensures member companies instil ethical trading practices.

We will continue to demonstrate our commitment to human rights by continuing to provide social elevation to workers across our value chain.